Unlocking the Potential of CNC Machine Supplies for Metal Fabricators

In the fast-paced world of metal fabrication, precision and efficiency are key drivers of success. As businesses strive to meet increasing demand while maintaining high standards of quality, the role of cnc machine supplies has become more vital than ever. This article delves into the multifaceted landscape of CNC supplies, offering insights into their importance, types, and how they can significantly enhance the operations of metal fabricators.

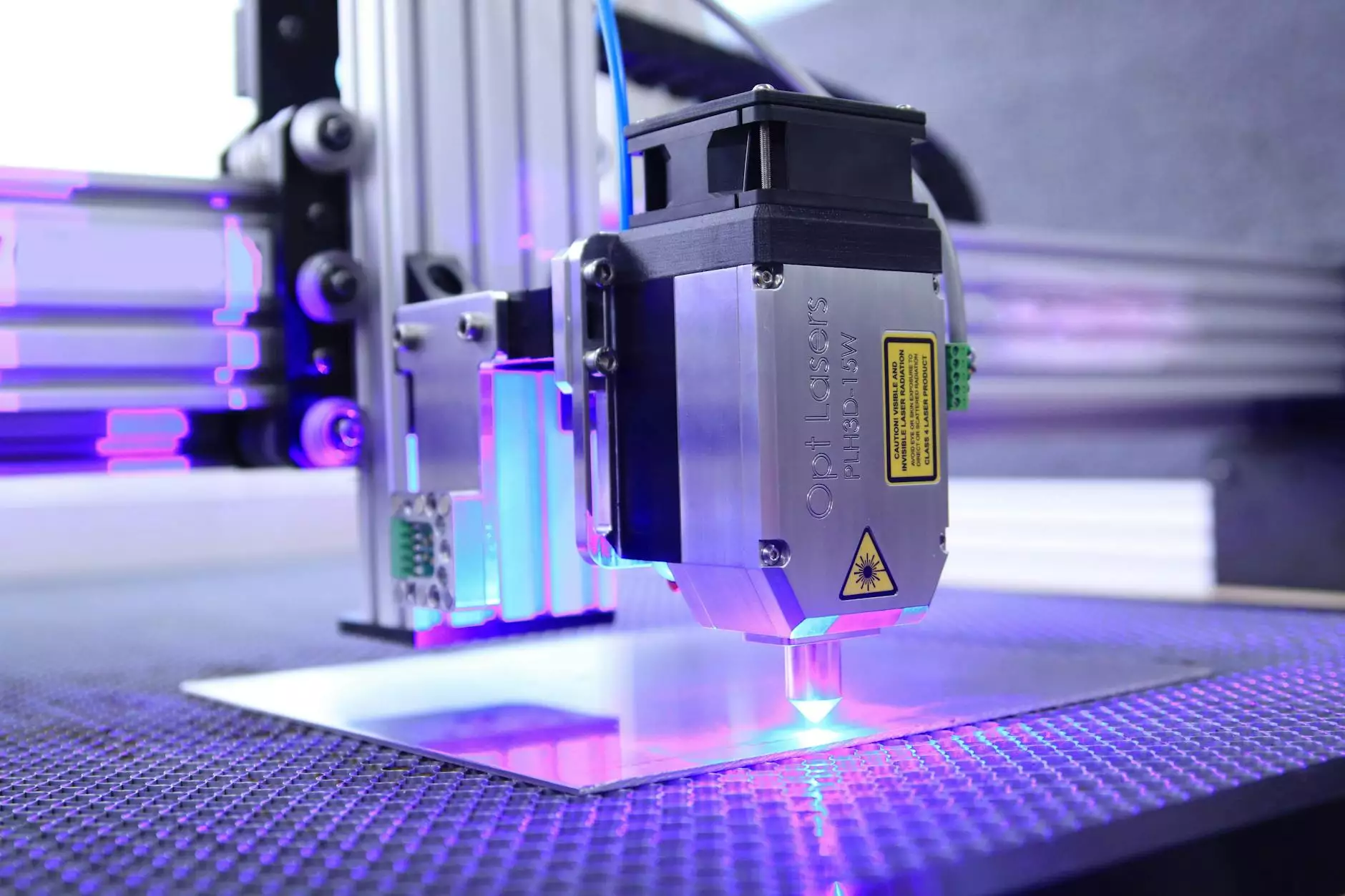

Understanding CNC Technology

CNC, or Computer Numerical Control, is a revolutionary technology that has transformed the manufacturing industry. By automating the machining process, CNC allows for precise control of machinery, leading to improved accuracy and reduced human error. This technology is essential for metal fabricators who require consistent and high-quality results in their projects.

Benefits of CNC in Metal Fabrication

- Increased Precision: CNC machines can perform intricate cuts and shapes that manual machining cannot achieve.

- Enhanced Productivity: Automation reduces the time required for production, allowing businesses to take on more projects.

- Consistency: With CNC machines, each product is manufactured to the exact specifications, ensuring uniform quality.

- Flexibility: CNC technology allows for quick adjustments to designs and production processes, adapting to changing demands.

The Importance of Quality CNC Machine Supplies

The effectiveness of CNC technology heavily relies on the quality of its supplies. Various components contribute to the overall performance of CNC machines, and understanding these components is crucial for metal fabricators.

Essential CNC Components and Supplies

Here's a breakdown of the key cnc machine supplies every metal fabricator should consider:

- Cutters and Tooling: Precision cutting tools, such as end mills, drills, and inserts, are vital for achieving desired shapes and finishes.

- Collets and Tool Holders: These components secure the cutting tools in place, impacting both the tool's stability and precision during operation.

- Workholding Systems: Devices such as vises, clamps, and fixtures hold the workpiece securely, ensuring stable machining processes.

- Control Software: Advanced software aids in the design, simulation, and optimization of machining operations, making it easier to achieve high levels of efficiency.

- Maintenance Supplies: Proper maintenance tools and lubricants are essential for keeping CNC machines in optimal condition, prolonging their lifespan.

Choosing the Right CNC Machine Supplies

Not all cnc machine supplies are created equal. Choosing the right components not only affects the machine's performance but also influences the overall productivity of the metal fabrication process.

Factors to Consider When Selecting CNC Supplies

- Material Compatibility: Ensure that the supplies chosen are suitable for the materials commonly used in your projects.

- Quality and Durability: Opt for high-quality supplies that can withstand the rigors of machining while providing long-lasting performance.

- Supplier Reputation: Work with reputable suppliers who offer reliable customer service and support, as this can significantly impact your operations.

- Cost-Effectiveness: While it can be tempting to choose the cheapest option, consider the long-term benefits of investing in quality supplies.

Enhancing Metal Fabrication with Advanced CNC Supplies

As the fabrication industry evolves, so do the tools and supplies available to enhance machining capabilities. Staying updated with the latest technologies can give your business a competitive edge.

Latest Innovations in CNC Machine Supplies

Recent advancements in CNC technology have led to the development of innovative supplies that further elevate machining processes:

- High-Speed Steel (HSS) Tools: These tools offer excellent rigidity and perform well at high speeds, increasing productivity.

- Ceramic Cutting Tools: Known for their hardness and thermal stability, ceramic tools are ideal for machining high-temperature materials.

- 3D Printing Components: Additive manufacturing is being integrated with CNC machining, allowing for complex geometries impossible with traditional methods.

- Smart Tools: Tools embedded with sensors provide real-time data about performance, helping fabricators monitor operations and adjust as needed.

Effective Maintenance of CNC Supplies

Maintaining CNC supplies is critical for ensuring the longevity and effectiveness of your machining operations. Here are some essential maintenance tips:

Regular Inspection and Care

Conduct routine checks on tools and components to identify any signs of wear or damage. This proactive approach prevents breakdowns and ensures uninterrupted production.

Lubrication and Cleaning

Proper lubrication minimizes friction and wear, while regular cleaning prevents debris build-up, which can affect the accuracy and performance of your CNC machines.

Calibration

Regularly calibrate CNC machines to ensure they operate within the desired specifications, which significantly impacts the quality of the finished products.

Investing in Training and Support

The effective use of cnc machine supplies goes beyond just having the right equipment. Investing in proper training for employees is essential to maximize the advantages these supplies offer.

Training Programs for Employees

Consider implementing training programs that focus on:

- Operating Procedures: Teach staff the correct methods of handling CNC machines and tools.

- Safety Protocols: Ensure that all personnel are aware of safety measures to prevent accidents in the workplace.

- Problem-Solving Skills: Equip employees with the skills to troubleshoot and solve issues that may arise during machining operations.

Conclusion: The Future of Metal Fabrication with CNC Machine Supplies

As metal fabrication continues to advance, the importance of high-quality cnc machine supplies cannot be overstated. Embracing the latest technologies, maintaining robust supply chains, and investing in employee training will position businesses for success in a competitive landscape.

At DeepMould.net, we are committed to providing metal fabricators with the best CNC supplies tailored to their unique needs. Through innovation and quality, we help you unlock the full potential of your operations, ensuring you stay ahead in the ever-evolving market. Make the smart choice today and enhance your manufacturing capabilities with our top-notch CNC machine supplies.